When talking about the production of the impressive Audi e-tron on the Brussels site, the batteries are an intriguing part of the driveline. We take a closer look at it here, and show you some very interesting drawings provided by Audi Media…

Hans Knol ten Bensel

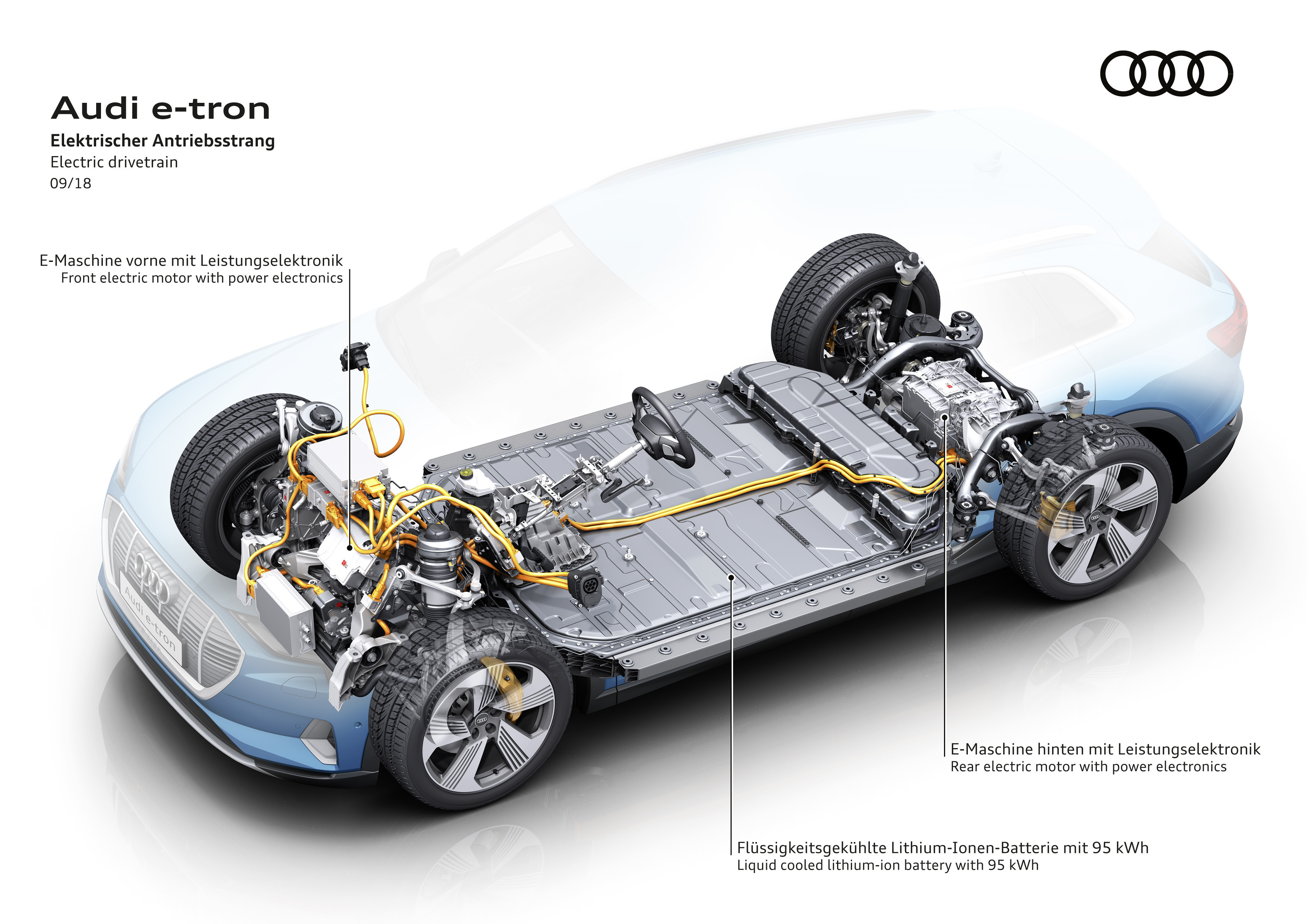

The large lithium-ion battery in the Audi e-tron provides for a range of more than 400 kilometers (248.5 mi) in the WLTP driving cycle. The battery operates with a nominal voltage of 396 volts and stores 95 kWh of energy.

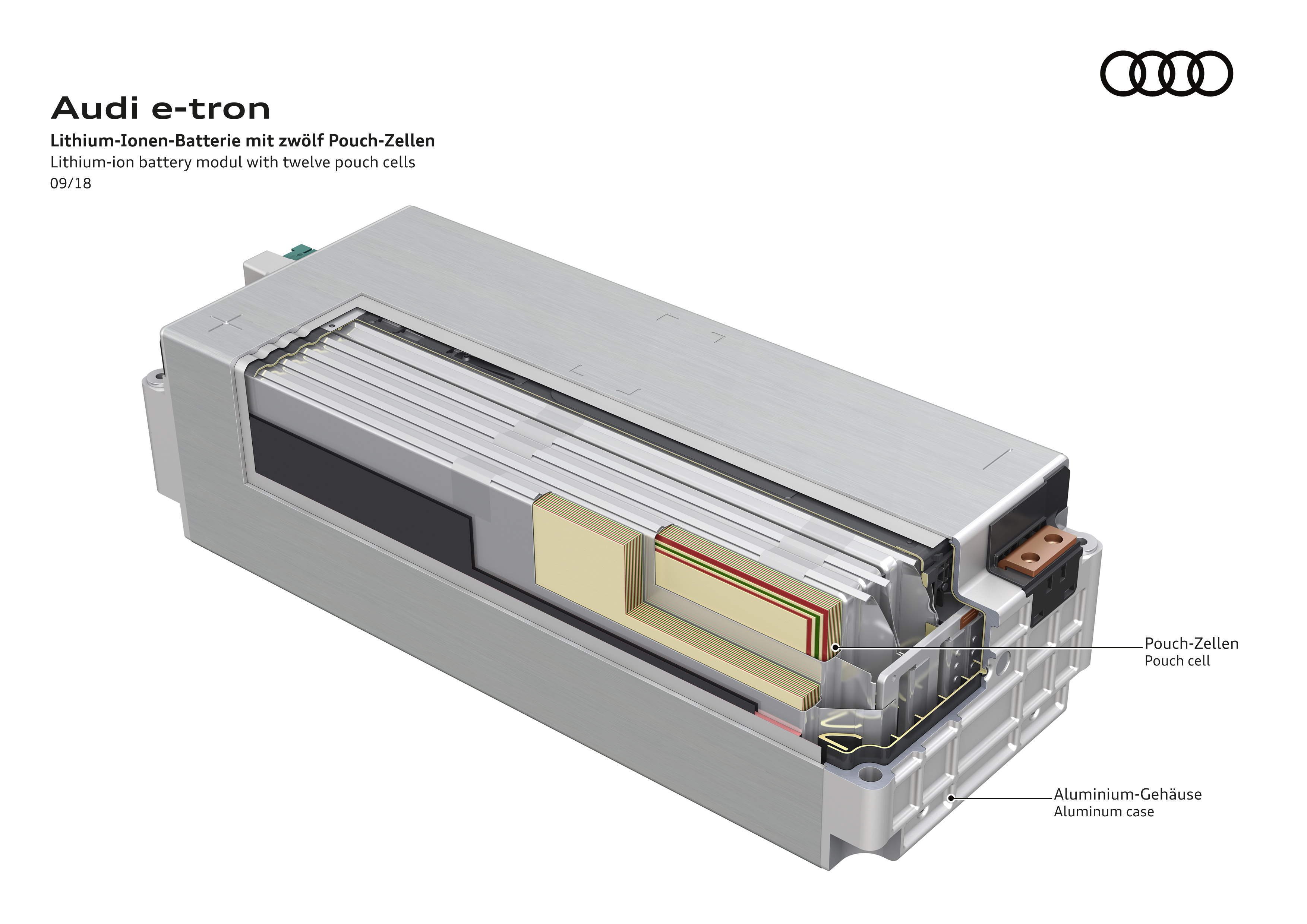

The battery system in the Audi e-tron is located beneath the cabin and is 2.28 meters (7.5 ft) long, 1.63 meters (5.3 ft) wide and 34 centimeters (13.4 in) high. It comprises a total of 36 cell modules in square aluminum housings, each of which is roughly the size of a shoe box. They are arranged on two levels, known as “floors” – a longer lower floor and a shorter upper one. At market launch, each module is equipped with twelve pouch cells having a flexible outer skin of aluminum-coated polymer. In the future, Audi will use both technically equivalent prismatic cells in its modular concept, also in terms of a multiple supplier strategy.

The cell modules in the Audi e-tron can reproducibly discharge and charge electricity over a broad temperature and charge status window. The can be densely packed to achieve a very high output and energy density in the volume available.

A cooling system of flat aluminum extruded sections divided uniformly into small chambers has the task of maintaining the battery’s high-performance operation over the long term. Heat is exchanged between the cells and the cooling system beneath them via a thermally conductive gel pressed beneath each cell module. In what is a particularly efficient solution, the gel evenly transfers the waste heat to the coolant via the battery housing. The cooling system is first fixed to the bottom of the battery tray with adhesive. To protect the cooling system against stone and road debris, a base plate is installed, also to improve aerodynamics. At assembly, first the batteries/modules on both floors are placed into their locations, then the gel (also called gapfiller) is applied.

The battery and all of its parameters, such as charge status, power output and thermal management, is managed by the external battery management controller (BMC). This is located in the occupant cell on the right A-pillar of the Audi e-tron.

The BMC communicates both with the control units of the electric motors and the cell module controllers (CMC), each of which monitors the current, voltage and temperature of the modules, 3 modules at the time. In the whole battery system, therefore 12 CMC’s are present. The battery junction box (BJB), into which the high-voltage relays and fuses are integrated, is the electrical interface to the vehicle. Enclosed in a die-cast aluminum housing, it is located in the front section of the battery system. Data exchange between the BMC, the CMCs and the BJB is via a separate bus system.

Sophisticated measures have been taken to protect the high-voltage battery of the Audi e-tron. A strong enclosing frame of cast aluminum nodes and extruded sections, plus an aluminum plate 3.5 millimeters (0.1 in) thick protect against damage from accidents or curbs. Inside, a framework-like aluminum structure reinforces the battery system. Also comprised of extruded sections, it holds the cell modules like a typecase.

Including the housing with its sophisticated crash structures comprising 47 percent extruded aluminum sections, 36 percent aluminum sheet and 17 percent diecast aluminum parts, the battery system weighs around 700 kilograms (1,543.2 lb). It is bolted to the body structure of the Audi e-tron at 35 points. This increases its torsional rigidity by 27 percent and contributes to the high level of the safety of the Audi e-tron, as does the cooling system bonded to the outside of the battery housing. Compared to a conventional SUV, the Audi e-tron offers 45 percent higher torsional rigidity, a key parameter for precise handling and acoustic comfort…

During production and assembly, utmost care is taken that screws which fix the modules into place do not cause insulation faults, and before the battery unit is cleared for further assembly, the differences in voltage between the cells and the modules are carefully controlled that it meets Audi Premium Standards. Finally leak tests are also carried out, both on the cooling system and the battery. Not less than 8 final tests are performed, before the battery is then partially (re)charged and fit for further assembly in the car.

Hans Knol ten Bensel