+

Without any doubt, the powerful rear engine Auto Unions were ahead of their time. Their sheer “Leistung” or power was absolutely legendary. Just tires couldn’t cope, and the sheer chassis dynamics and even more importantly aerodynamics were not fully understood at the time. So the cars had no downforce at racing speeds, and the narrow tires with their still softer construction and not so adhesive compounds did not help.

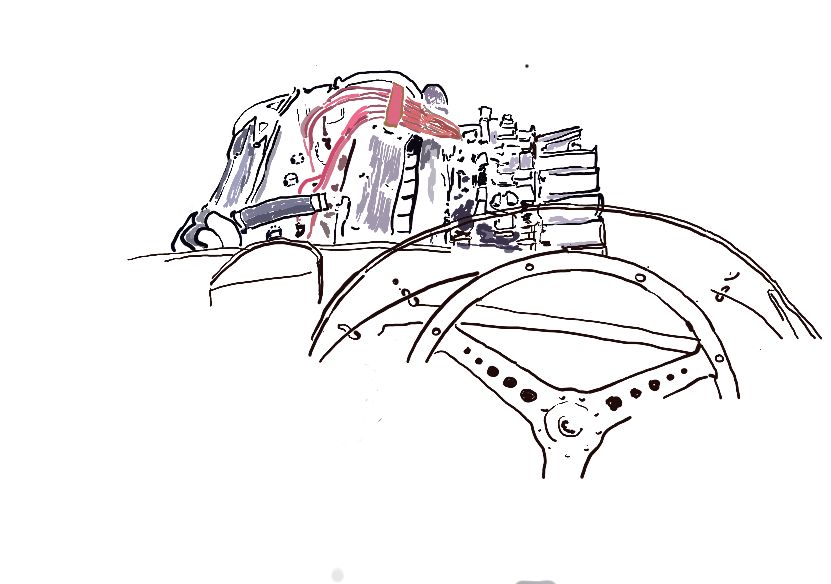

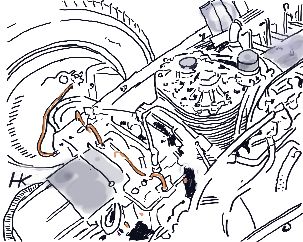

The V16 engine of this Type C was a Porsche design, and started off in the type A with a displacement of 4360 cc. But it was originally meant to be a 6 litre engine, and this it was in the Type C. The two cylinder banks were angled at 45 degrees, and one central camshaft operated all the 32 valves. That is why the engine has this typical look of 16 pushrods in their gleaming chromed shafts connected with the exhaust valves, while the intake valves were actuated by the camshaft through rocker arms. So we see three valve covers on this beautiful engine.

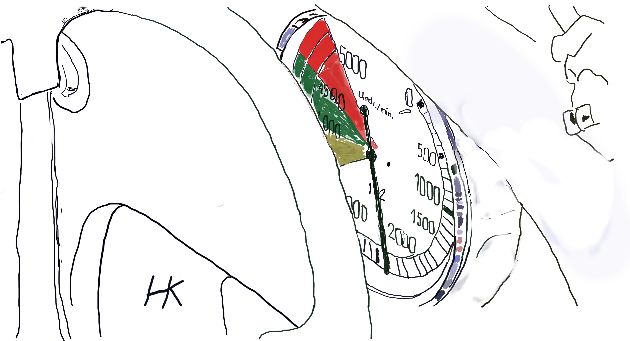

The engine was laid out to develop massive low end torque, and for a racing engine, it revved quite low, as the rev counter clearly tells.

All this torque, a hefty 853 Nm being available at 2500 rpm, was very difficult to handle for the narrow rear wheel tires, and a limited slip differential was badly needed to stop the inner wheel in narrow corners from spinning fiercely through under full throttle, even in the dry!

The impressive two-stage Roots compressor at the back of the engine, fed by a battery of two carburetors…

Maximum power ranged from 485 to 520 PS or 357-382 kW during the racing seasons, and whether the race was to be long or short. It was achieved at – at least for a racing engine –a very lowish 5000 rpm. A two stage roots compressor was used, with 0,95 bar pressure.

One last item, which one tends to forget when talking about the sheer performance of this engines, is that the 200 L tank did not contain ordinary fuel. A (secret) mixture using amongst others ethanol and methanol was used. This did allow higher combustion chamber pressures and temperatures, without problems of knocking or lack of cooling. One needs to flush the system after races because the mixture is corrosive.

In our next edition, we will go for the equally stunning Alfa Romeo P2 straight 8 compressor engine…

We just let you look here at our drawings!

Hans Knol ten Bensel